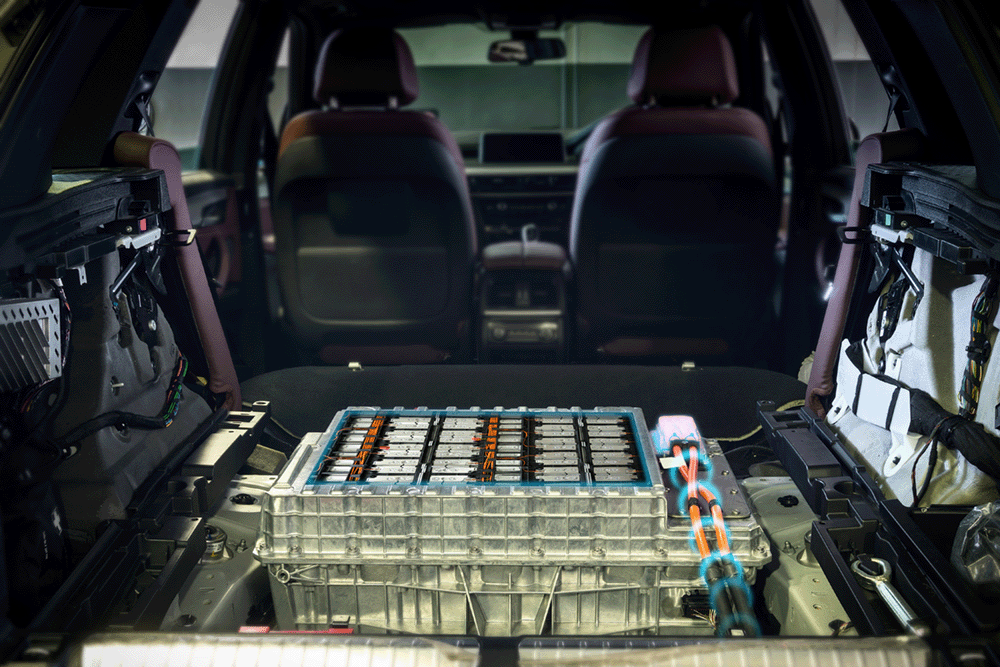

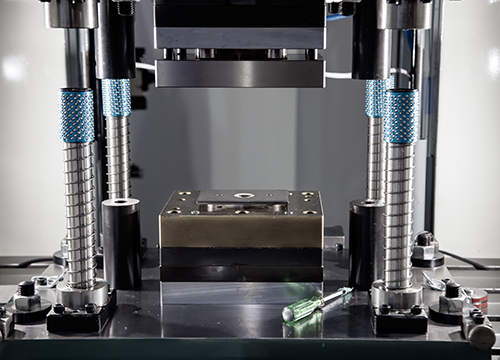

Automotive / EV Battery / Pressing

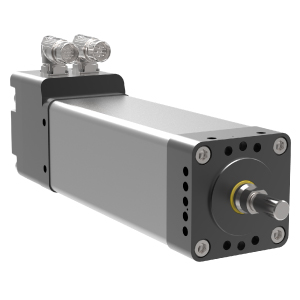

Automobile manufacturing processes require high force density, precision, reliability and long life. Exlar® high performance automotive industry Actuators deliver all that and much more. Our unique roller screw driven solutions provide superior power, speed, precision, flexibility, efficiency and long life that can’t be matched by hydraulic, pneumatic or electric ball screw driven actuators.

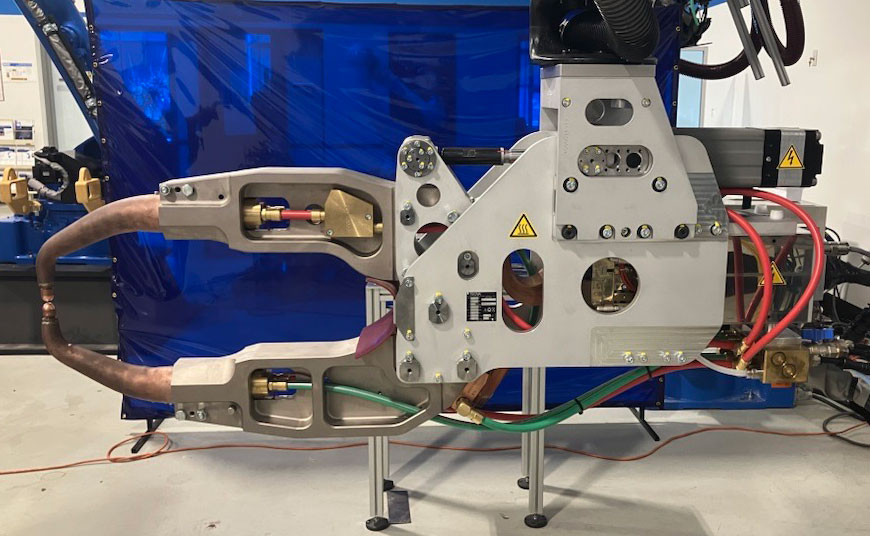

Pressing

Pressing