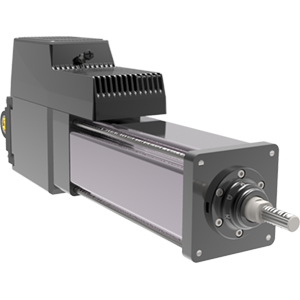

Dispensing / filling / injecting - Exlar® electromechanical actuators allow for precise depositing of liquids, gels, foods, and plastics. These applications often require flexibility, precision, speed, and 24/7 operation, making Exlar actuators the ideal choice.

Slicing / Processing / mixing - Slicing or cutting in any manufacturing process requires accuracy and repeatability for desired tool life and reduced downtime. Exlar® electromechanical actuators can eliminate unnecessary crashing or damage to cutting and processing tools.

Sealing / pressing - Exlar® electromechanical actuators can be used for sealing These applications often require force repeatability, speed, and 24/7 operation, making Exlar actuators the ideal choice.

Forming / packaging - As consumer demand for variety increases, packaging equipment must become more flexible, adapting to more challenging shapes and sizes. Exlar® electromechanical actuators can be preprogrammed to adapt to a near infinite number of profiles, available at the touch of a button.

Molding - Molding applications can have challenges associated with impact loads and heat. Exlar® electromechanical actuators driven with roller screws and lubricated with oil make an ideal choice for these applications.

Diverting/material handling - The robustness of Exlar® electromechanical actuators have been proven to handle the roughest of environments.