HIGH PERFORMANCE ACTUATORS FOR THE AUTOMOTIVE INDUSTRY

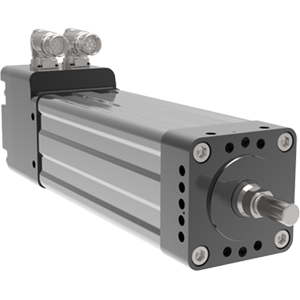

Exlar electric actuators not only outperform competing technologies, they’re built to last. Our products are successfully installed in automobile and related component manufacturing facilities in the United States, Canada, Mexico, South America, China, Germany, France, the United Kingdom, Italy, Poland and the Czech Republic. Our complete line of electric actuators give you the power and speed of a muscle car, the flexibility and long life of an SUV with the efficiency and relative size of an ultra compact. And, with our small form and configurable solutions, replacement of your existing hydraulic and pneumatic systems is a breeze.

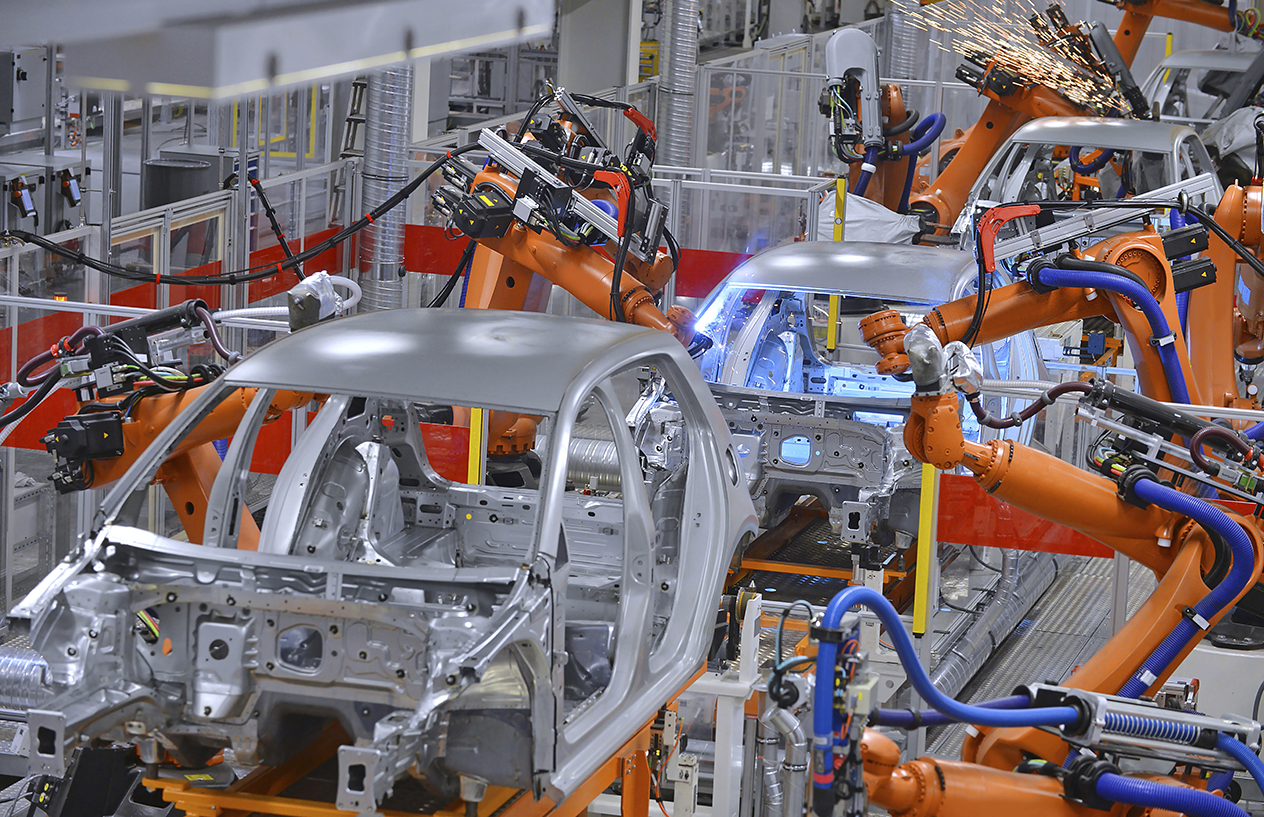

Linear actuation is a core technology for factory automation. Along with fluid power, electromechanical actuators have become increasingly important. However, air and oil systems are riddled with inefficiencies and are difficult to control. A comparison of the three actuator technologies (hydraulic, pneumatic and electromechanical) reveals startling benefits of electromechanical solutions when compared to to additional fluid power. In the automotive industry today, robotic weld guns represent the most prevalent linear actuator application being converted from fluid power to electromechanical.

Robots are used in automotive production plants throughout the world. The main application for robots is spot welding of stamped sheet metal parts. Accuracy and repeatability are important to guarantee a quality vehicle chassis as the foundation of the build. Electric actuators are replacing hydraulic and pneumatic versions because they have been shown to be more accurate, repeatable and long-lasting.

Bending - Today’s manufacturing processes require precise control, especially when the application requires bending definable angles in multiple planes. Exlar® actuators provide the accuracy and flexibility needed for the most demanding applications.

Dispensing - Exlar® electromechanical actuators allow for precise depositing of adhesives, sealants, grease, and lubricants minimizing environmental damage and cost. Perfect for dispensing the exact amount of gel repeatedly to save cost in battery cell manufacturing.

EV Battery Manufacturing - Improving automation of the Electric Vehicle (EV) battery production process is the highest priority as the EV industry scales-up to meet the increasing demand. Partnering with the right company who manufactures high-performance electromechanical actuation products is critical to meeting that demand. Exlar® electromechanical actuators are globally recognized as a leading brand offering: high power density, precision, reliability.

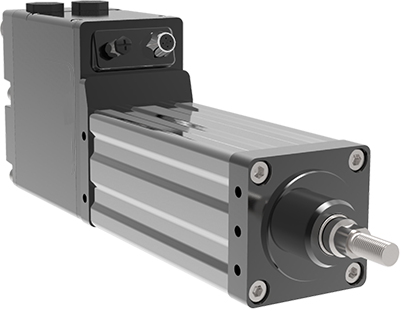

Flexible Tooling - Intelligent, networkable electro-mechanical actuators from Exlar® provide precise, programmable force control for a wide range of factory automation tooling applications. Exlar actuators are an ideal replacement for less flexible traditional fluid power solutions, including both pneumatic and hydraulic cylinders.

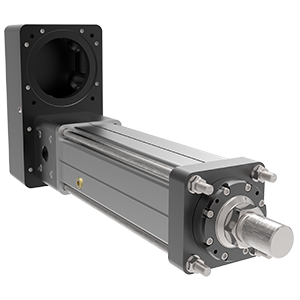

Pressing - Roller screw driven electro-mechanical actuators from Exlar are an ideal alternative to messy, maintenance-prone hydraulic cylinders in high force press applications. In a variety of related metal forming assembly processes, including pressing, inserting, crimping, and riveting, Exlar® actuators provide precise and repeatable force application over millions of cycles with minimal maintenance required.

Robotic Welding - Exlar Automation’s integrated electromechanical actuators seamlessly integrate as the 7th axis on robots from a majority of the leading global industrial robot manufacturers. Exlar actuators drive end of arm tooling for a wide variety of applications including resistive spot welding, fluid dispensing, and clamping.

Exlar Automation has successfully integrated actuators with robot controllers from the following manufacturers: Yaskawa, Fanuc, Comau, KUKA, Kawasaki, ABB, Nachi.

Contact Exlar for assistance in configuring your application.