Exlar Electromechanical Actuators for Food & Beverage / Packaging

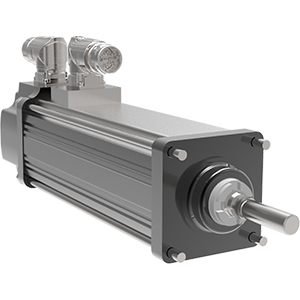

Exlar offers reliable roller screw driven electromechanical actuators configured to meet the harsh demands of washdown environments in food & beverage applications, and the high speed/high duty cycle demands in packaging applications.

Electromechanical actuators are an ideal replacement for fluid powered actuation for those OEM’s looking to improve overall equipment effectiveness(OEE) with advantages in these areas:

- Reliable to eliminate failures and downtime

- Flexible/programable to changeover product on the fly

- Accurate and repeatable to increase quality and reduce waste

- Efficient to reduce power machine power consumption

- Oil free to eliminate potential leaks and maintenance

- Electric to eliminate the need for pumps, compressors, hoses

- Quite to eliminate noise from pumps and compressors

***Check out our latest in white papers and success stories below***

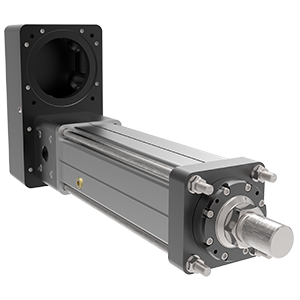

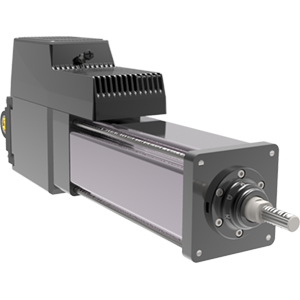

Exlar electromechanical actuators transmit torque from the motor to force at the rod end using precision ground roller screws, these screws can provide advantages over other electromechanical linear technologies in these areas:

- High rigidity - increases accuracy

- Life - up to 15x longer than ball screws, even longer when compared to other screw technologies

- Able to withstand high shock and vibration

- Able to be taken apart for regreasing in the field

TURNING MOTION INTO ACTION

Actuators Improve Overall Equipment Effectiveness

With increasing concerns surrounding food safety, hydraulic systems are no longer desirable in food-producing companies due to the potential risks of food contamination from oil leakage. Electromechanical actuators are ideally suited to meet the requirements governing food processing, while eliminating the need for hydraulic oil, pumps, hoses, filters, etc. Maintenance can also be kept to a minimum, eliminating the need for frequent oil and filter changes. Electromechanical actuators are the very best when accuracy and repeatability are required, so exact portion control can be met. Read more about How Electric Actuation Saved Switzerland’s Leading Milk Processor 60% in Power Consumption

Dispensing / filling / injecting - Exlar® electromechanical actuators allow for precise depositing of liquids, gels, foods, and plastics. These applications often require flexibility, precision, speed, and 24/7 operation, making Exlar actuators the ideal choice.

Slicing / Processing / mixing - Slicing or cutting in any manufacturing process requires accuracy and repeatability for desired tool life and reduced downtime. Exlar® electromechanical actuators can eliminate unnecessary crashing or damage to cutting and processing tools.

Sealing / pressing - Exlar® electromechanical actuators can be used for sealing These applications often require force repeatability, speed, and 24/7 operation, making Exlar actuators the ideal choice.

Forming / packaging - As consumer demand for variety increases, packaging equipment must become more flexible, adapting to more challenging shapes and sizes. Exlar® electromechanical actuators can be preprogrammed to adapt to a near infinite number of profiles, available at the touch of a button.

Molding - Molding applications can have challenges associated with impact loads and heat. Exlar® electromechanical actuators driven with roller screws and lubricated with oil make an ideal choice for these applications.

Diverting/material handling - The robustness of Exlar® electromechanical actuators have been proven to handle the roughest of environments.