|

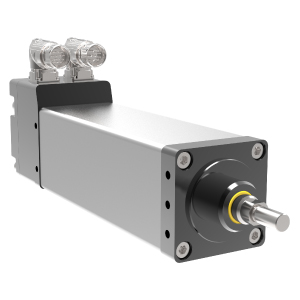

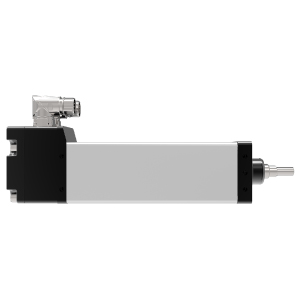

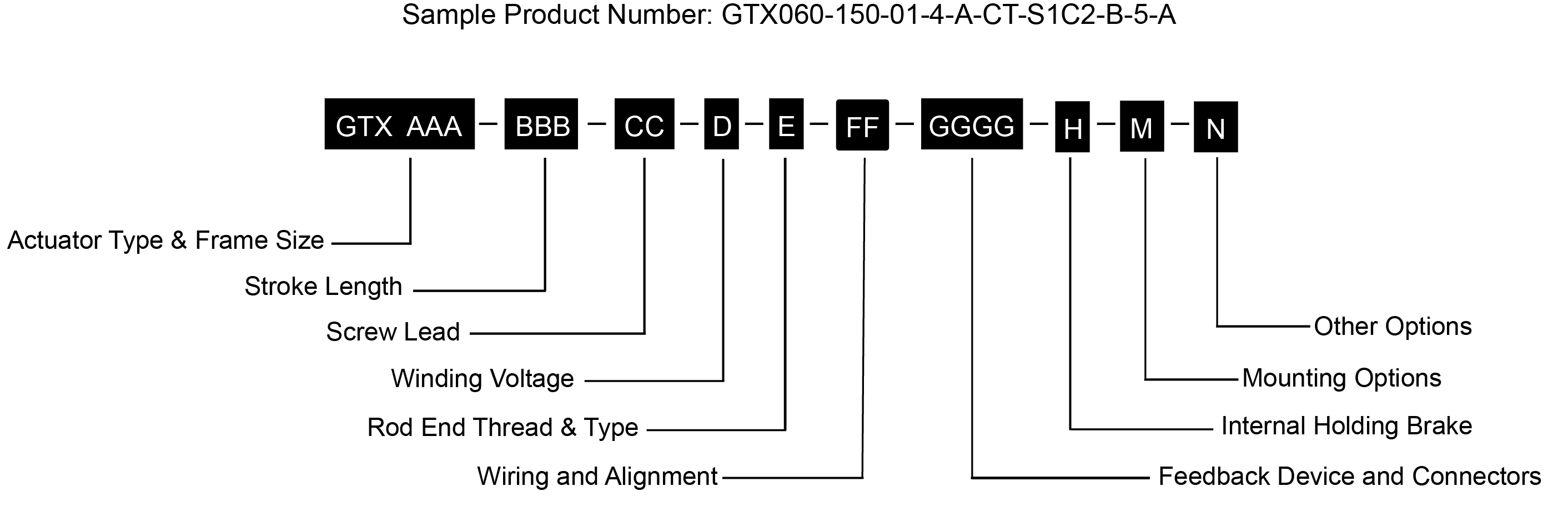

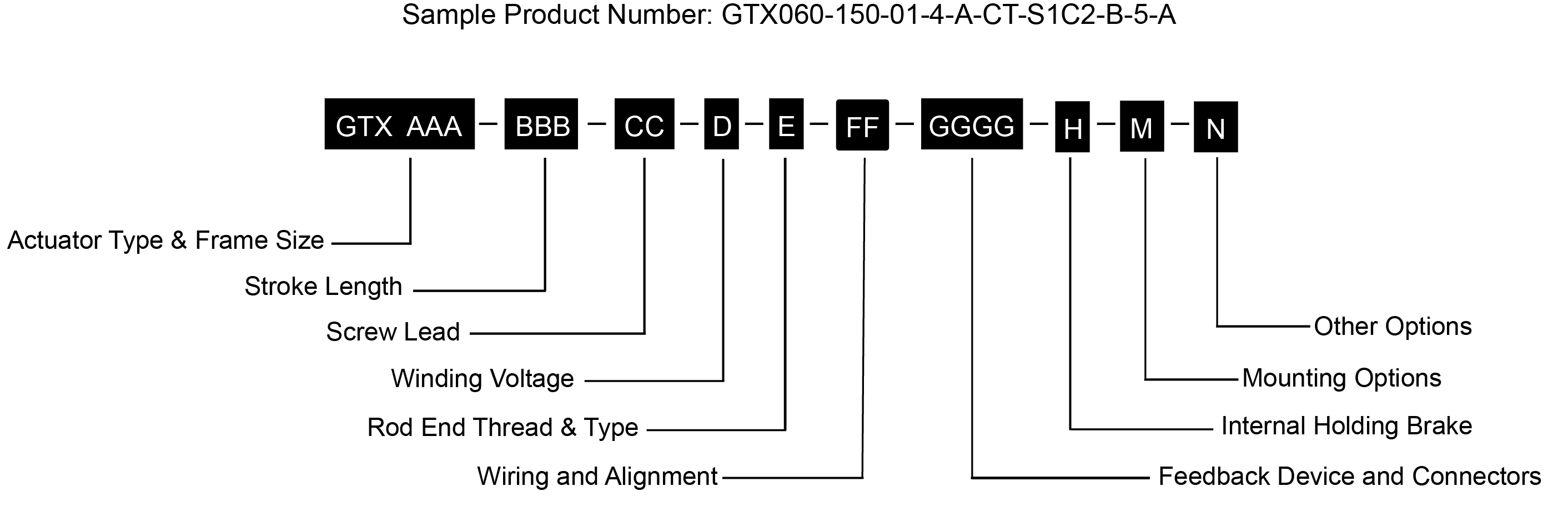

AAA = GTX Integrated Motor / Actuator

060 = 60 mm (2.36 in)

080 = 80 mm (3.15 in)

100 = 100 mm (3.94)

BBB = Stroke Length

080 = 80 mm (GTX060)

100 = 100 mm (GTX060, GTX080)

150 = 150 mm

300 = 300 mm

450 = 450 mm (GTX080)

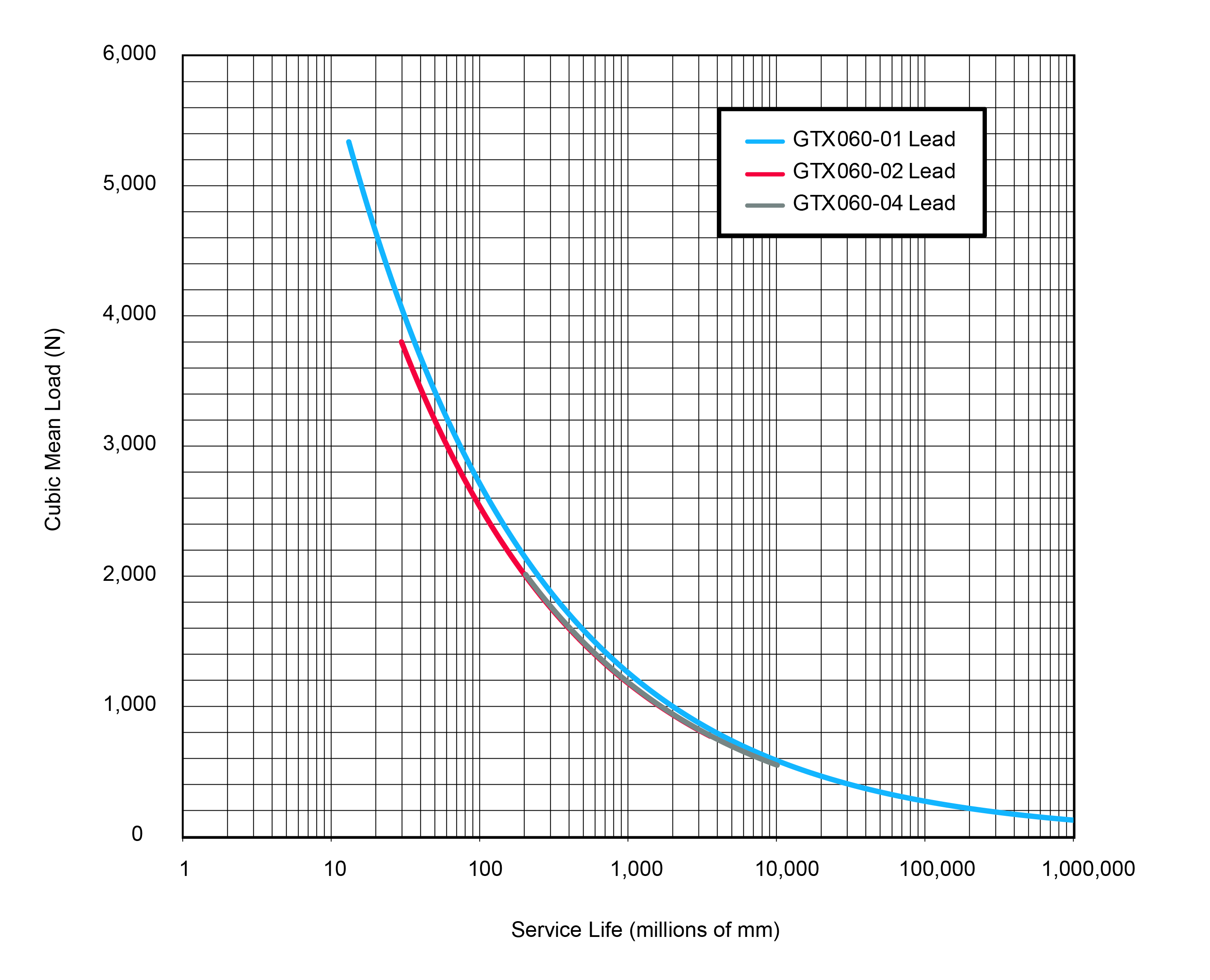

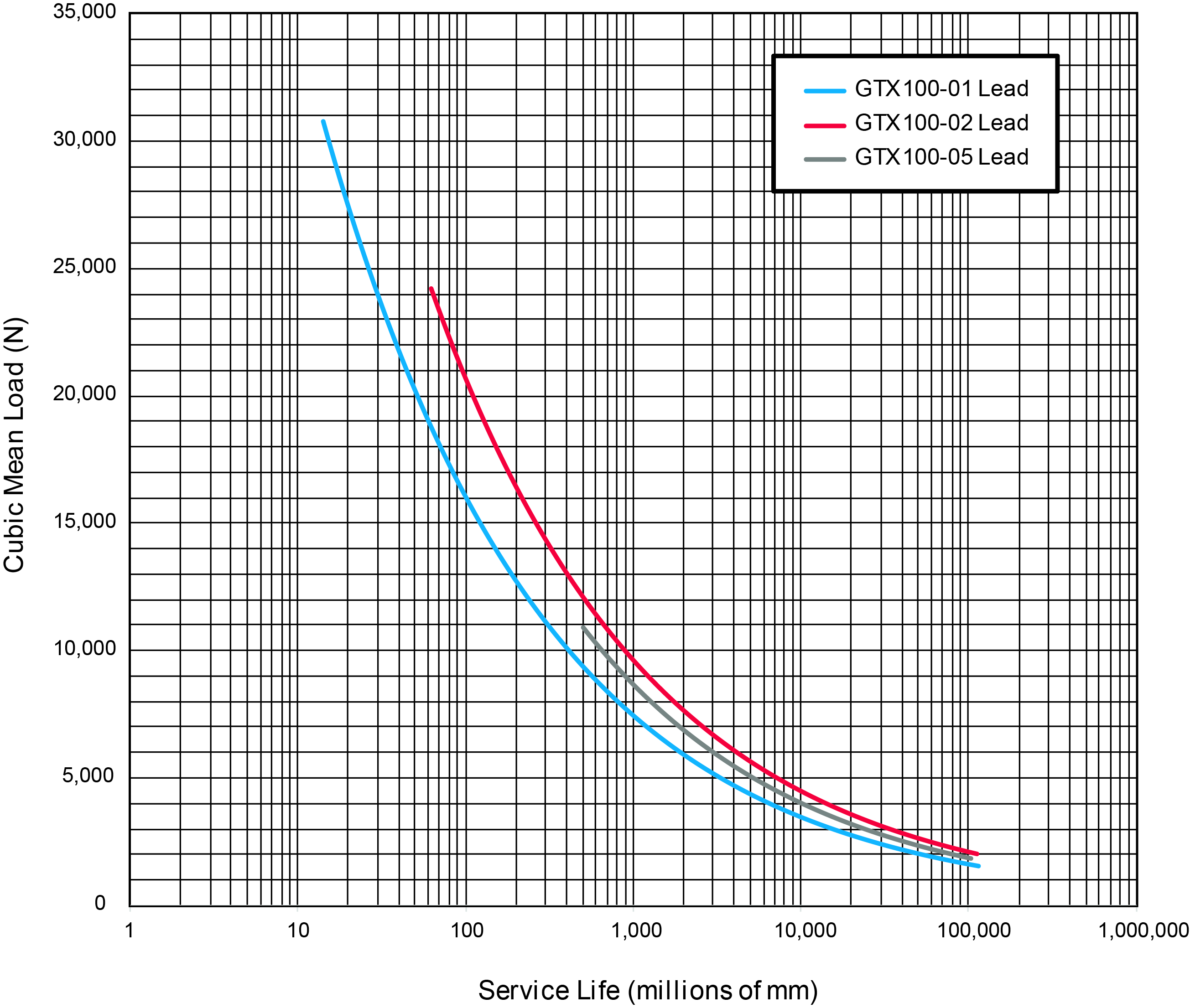

CC = Screw Lead

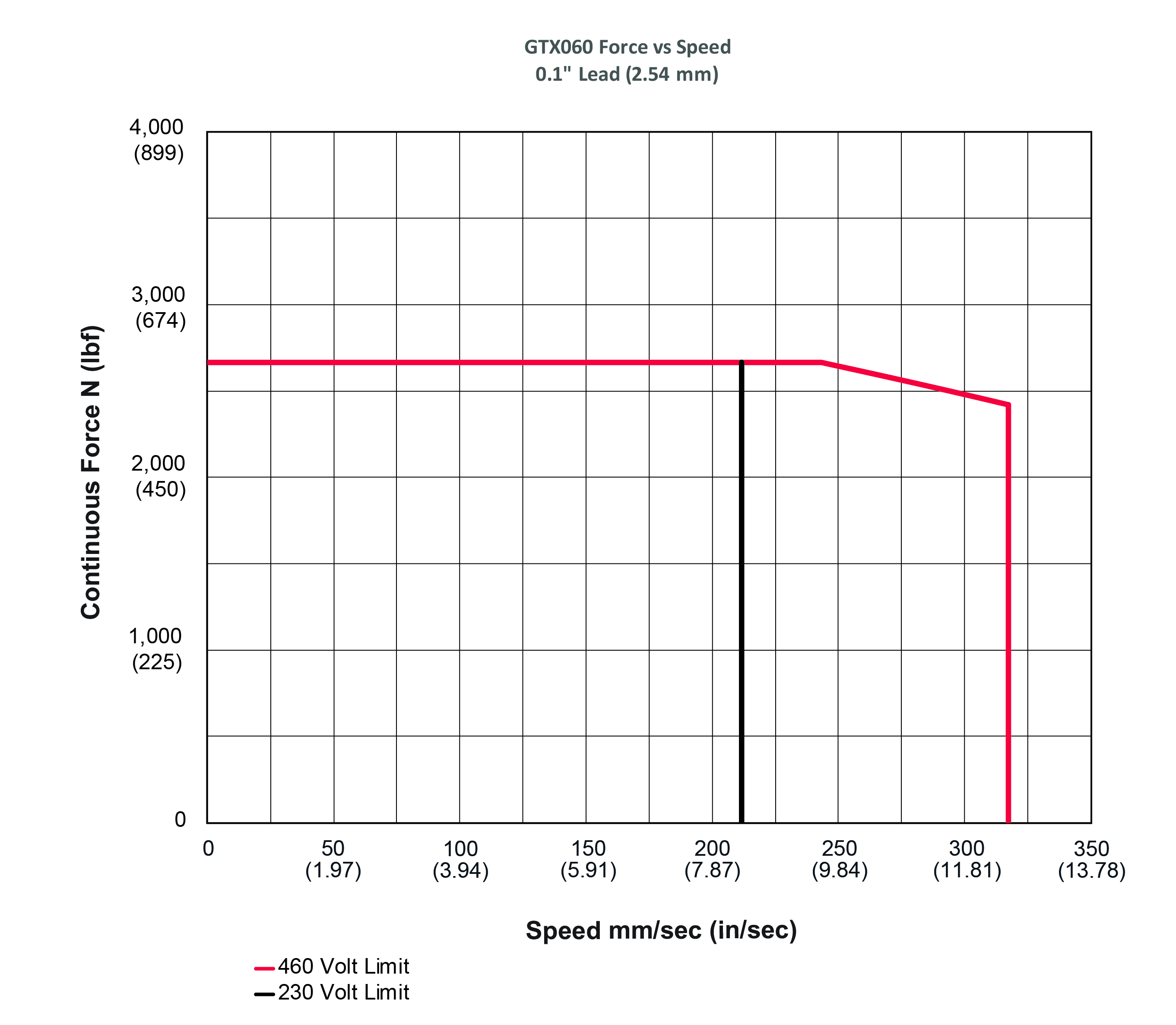

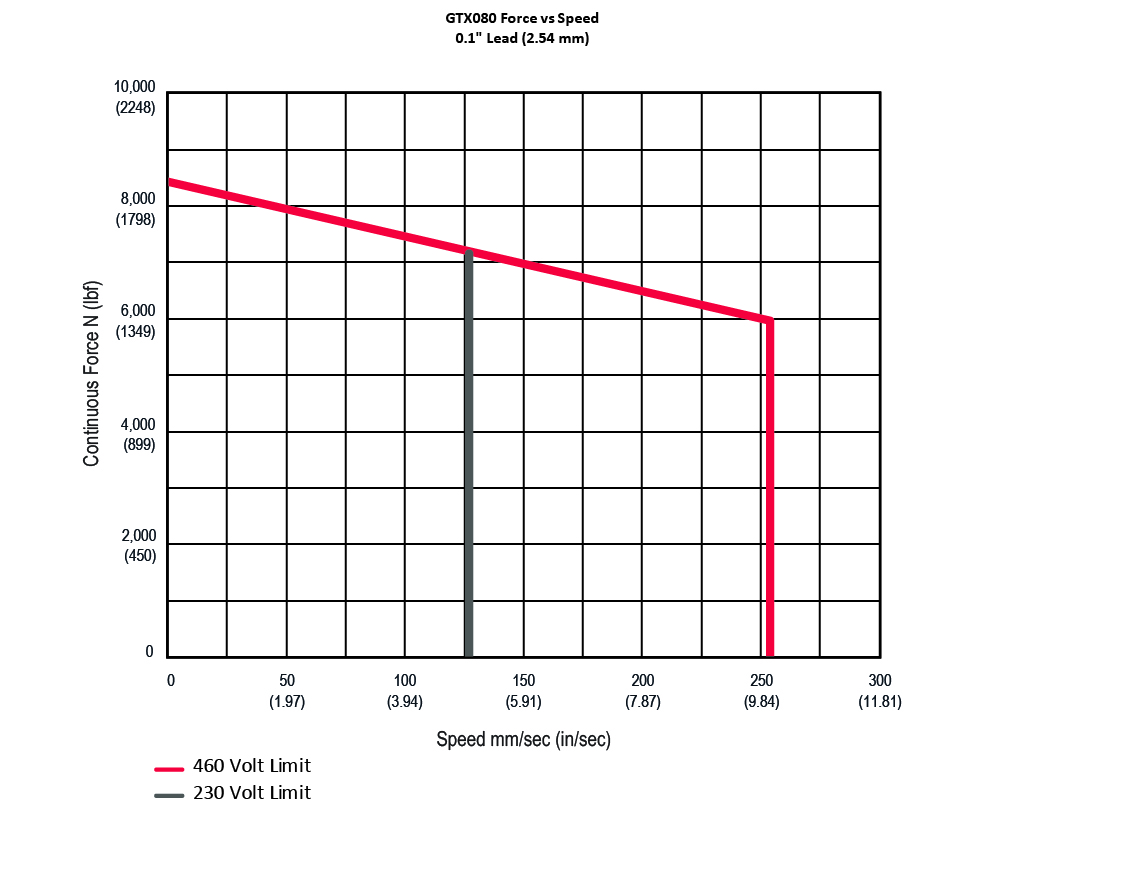

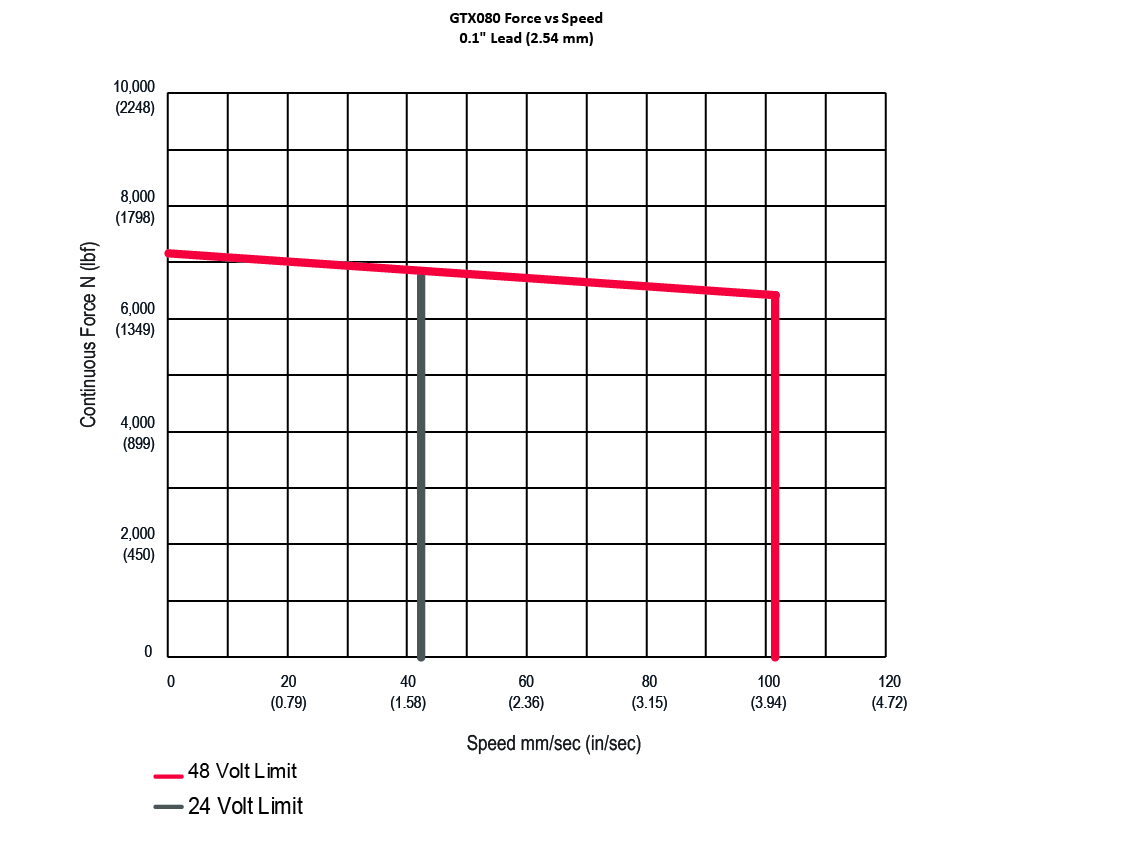

01 = 2.54 mm (0.10 in)

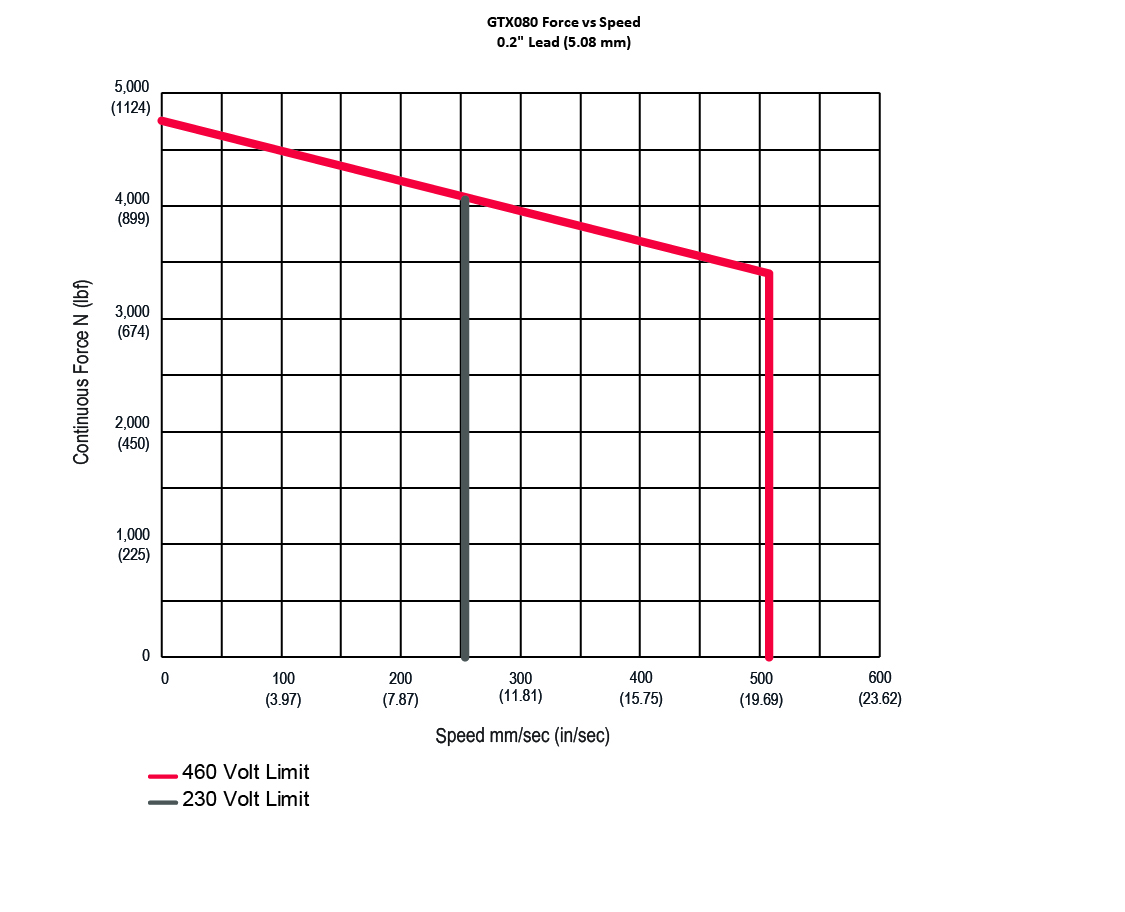

02 = 5.08 mm (0.20 in)

04 = 10.16 mm (0.40 in) GTX060

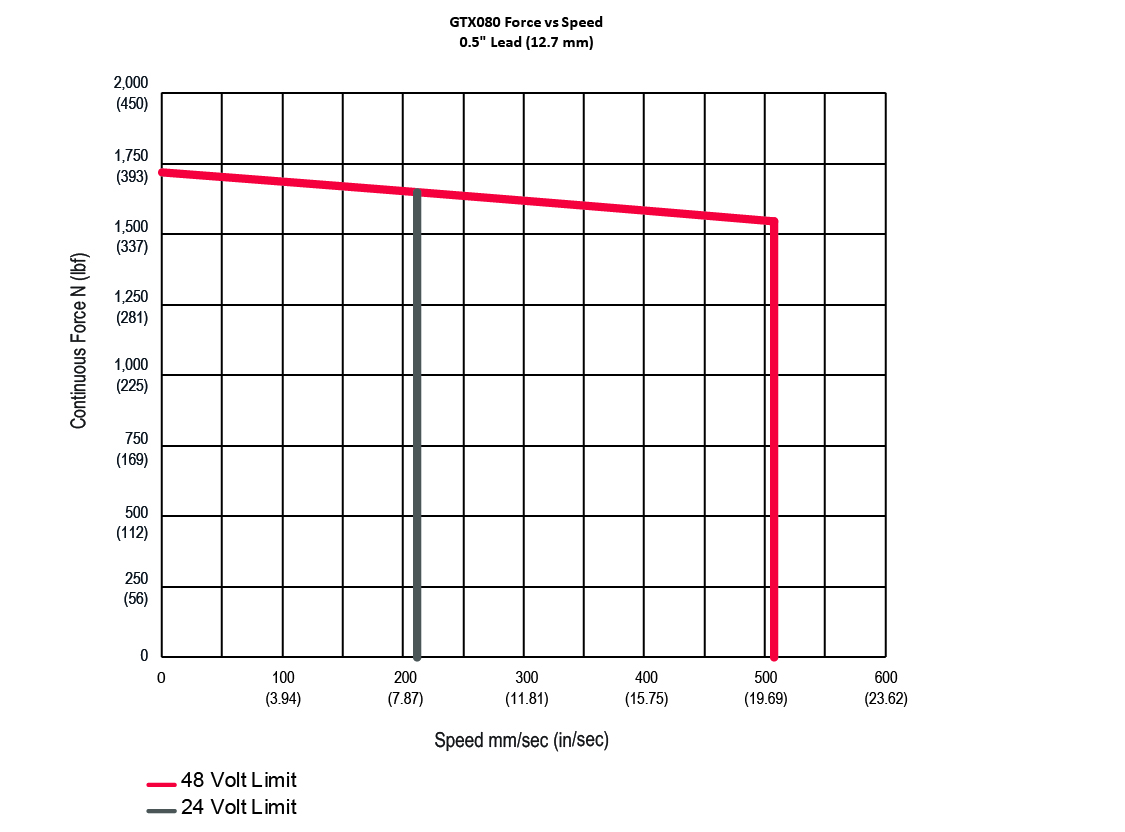

05 = 12.7 mm (0.50 in)

D = Winding Voltage

4 = 460 VAC Max

D = 48 VDC Max (GTX060, GTX080)

E = Rod End Thread & Type

A = Male Metric Thread

B = Female Metric Thread

C = Male Metric Thread, Splined2

D = Female Metric Thread, Splined2

F = Female Standard Thread

G = Male Standard Thread, Splined2

H = Female Standard Thread, Splined2

L = Female Metric Thread, 17-4 SS

M = Male Standard Thread

R = Male Metric Thread, 17-4 SS

V = Female Standard Thread, 17-4 SS

W = Male Standard Thread, 17-4 SS

|

FF = Wiring and Alignment

AK = AMK

BR = B&R Automation

BD = Baldor

BE = Beckhoff

BM = Baumueller

CT = Control Techniques / Nidec

EU = Elau / Schneider Electric

EL = Elmo Motion Control

EX = Exlar

IF = Infranor

IN = Bosch-Rexroth

KM = Kollmorgen

LS = LTI

LZ = Lenze

PC = Parker

RA = Rockwell Automation

SM = Siemens

SB = Stober Drives

GGGG = Feedback Device and Connectors

See table below

H= Internal Holding Brake

N = No Brake

B = Internal Holding Brake, Electronically Released

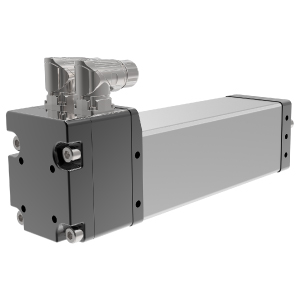

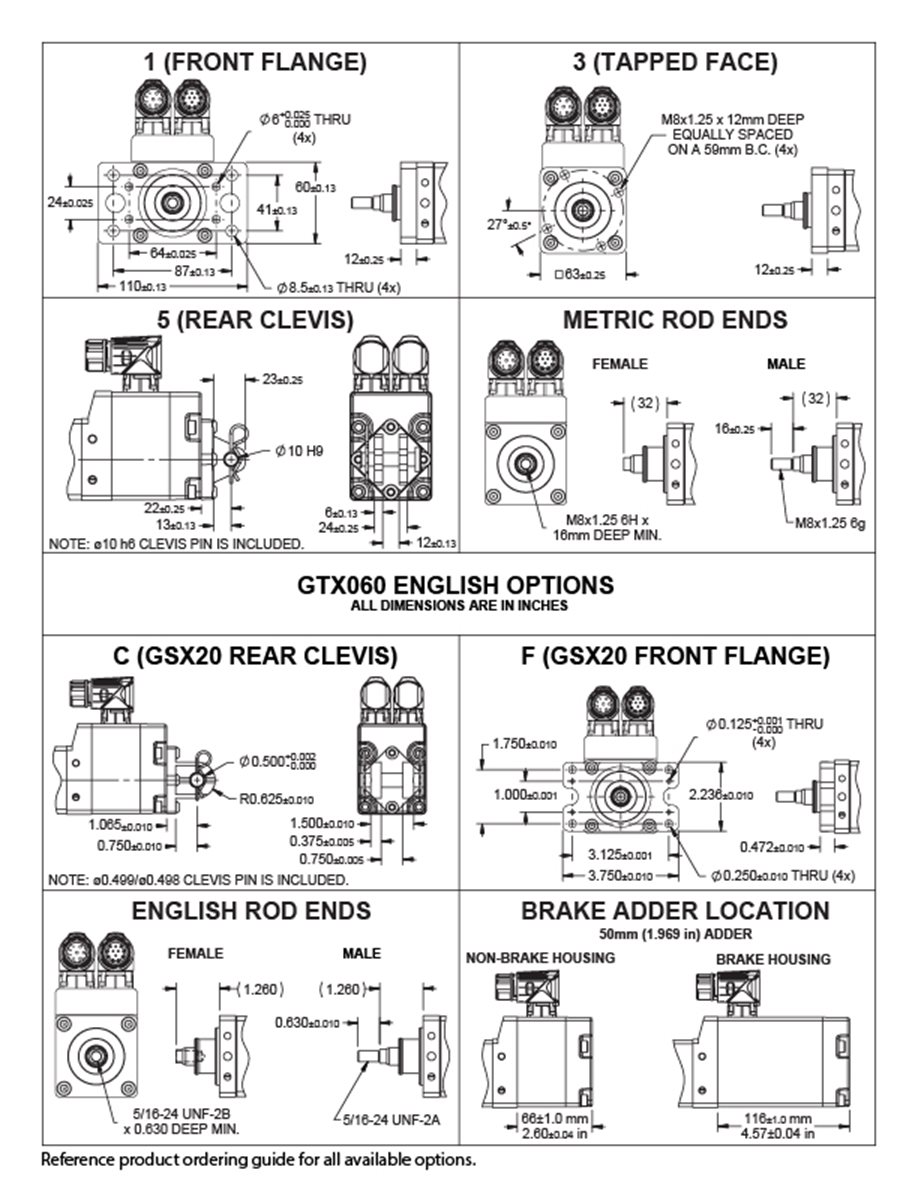

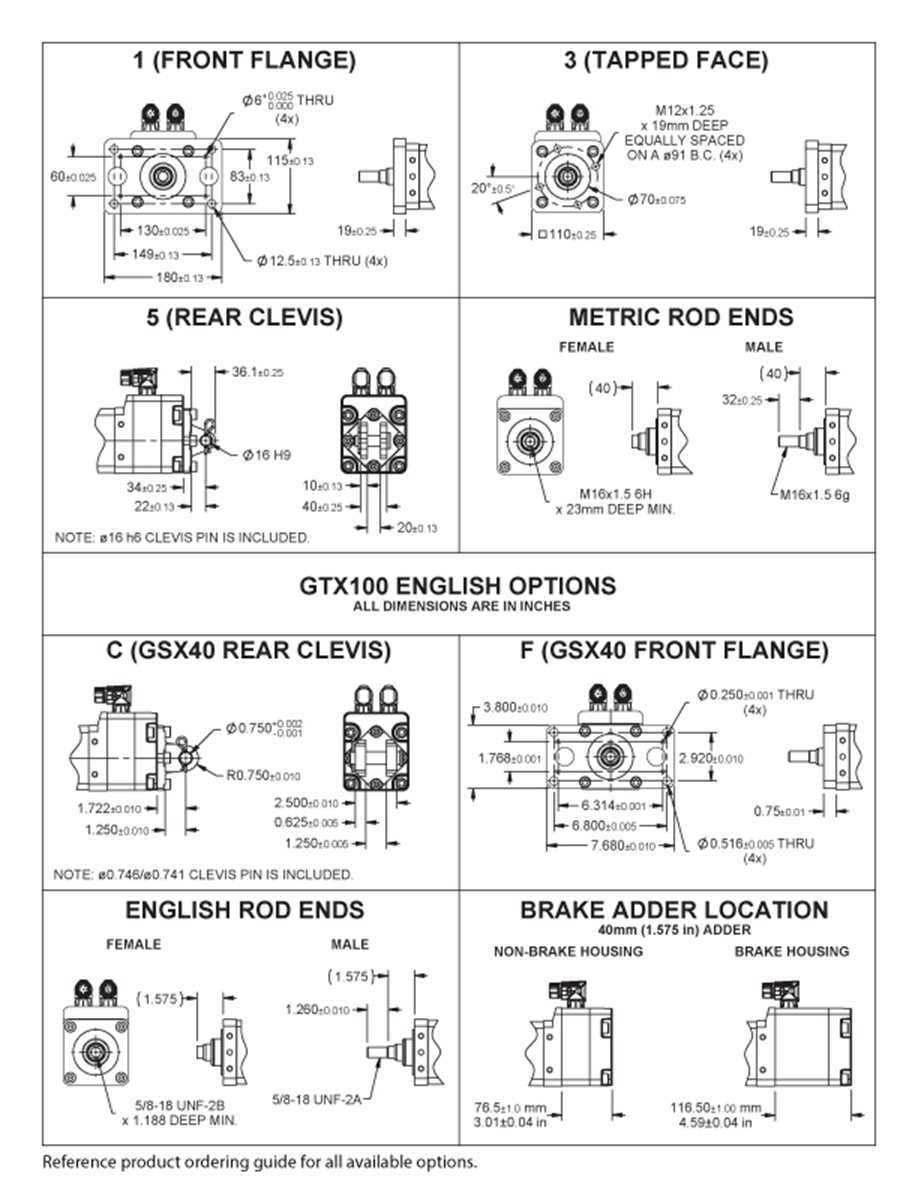

M = Mounting Options

N = None

1 = Front Flange, Metric

3 = Tapped Face, Metric

5 = Rear Clevis, Metric

F = Front Flange, Standard

C = Rear Clevis, Standard

N = Other Options

N = None

A = Anti-Rotate Assembly, External

L = Limit Switch Housing/ Anti-Rotate Assembly1

|

NOTES:

1 Switches sold separately

2 Splined Rod (Internal Anti-Rotate) option reduces IP rating.

|

Drive Manufacturer

|

Wiring &

Alignment Code

|

Resolver

|

Incremental

Encoder

|

SICK Hiperface Absolute Encoder

|

SICK Hiperface DSL Absolute Encoder

|

Heidenhain EnDat 2.1 Absolute Encoder 1

|

Heidenhain EnDad 2.2 Absolute Encoder 2 |

|

AMK

|

AK

|

R1A1

|

|

|

|

H1A1

|

|

|

B&R Automation

|

BR

|

R1A1

|

|

|

|

H1A2

|

H3A83 |

|

Baldor

|

BD

|

R1A1

|

|

|

|

H1A1

|

|

|

Baumueller

|

BM

|

R1A1

|

|

S1A1

|

|

H1A2

|

|

|

Beckhoff

|

BE

|

|

|

|

S4C03

|

H1A2,

|

H3C23 |

|

Control Techniques

|

CT

|

R2B1

|

E1B2

|

S1B1

|

|

H1B2

|

|

|

Elau

|

EU

|

|

|

S1A14

|

|

|

|

|

Elmo Motion Control

|

EL

|

R1B1

|

E1B2

|

|

|

H1A2

|

|

|

Exlar

|

EX

|

R1A1

|

E1A2

|

S1A2

|

|

H1A2

|

|

|

Infranor

|

IF

|

R1B2

|

|

S1B2

|

|

|

|

|

Bosch-Rexroth

|

IN

|

|

|

S2D34

|

|

H1D3

|

|

|

Kollmorgan

|

KM

|

R2A1

|

E1A2

|

|

|

H1A2

|

|

|

LTI

|

LS

|

R2A1

|

|

S1A2

|

|

|

|

|

Lenze

|

LZ

|

R1B1

|

|

S1B1

|

|

|

|

|

Parker

|

PC

|

R1B1

|

E1B2

|

|

|

H1B2

|

|

|

Rockwell Automation

|

RA

|

|

E1C2

|

S1C24

|

S3CO4

|

|

|

|

Siemens

|

SM

|

R1B1

|

|

|

|

H1B2

|

|

|

Stober Drives

|

SB

|

R4A1

|

|

|

|

H1A1

|

|

1Synchronous serial EnDat 2.1 with 1 Vpp Incremental Signals (EnDat01)

2Synchronous serial EnDat 2.2 without Incremental Signals (EnDat22)

3Supports Functional Safety

4Encoder is pre-programmed for operation with the manufacturer's servo drives.

** Some options are not available with every configuration. For options or specials not listed above contact your local representative.

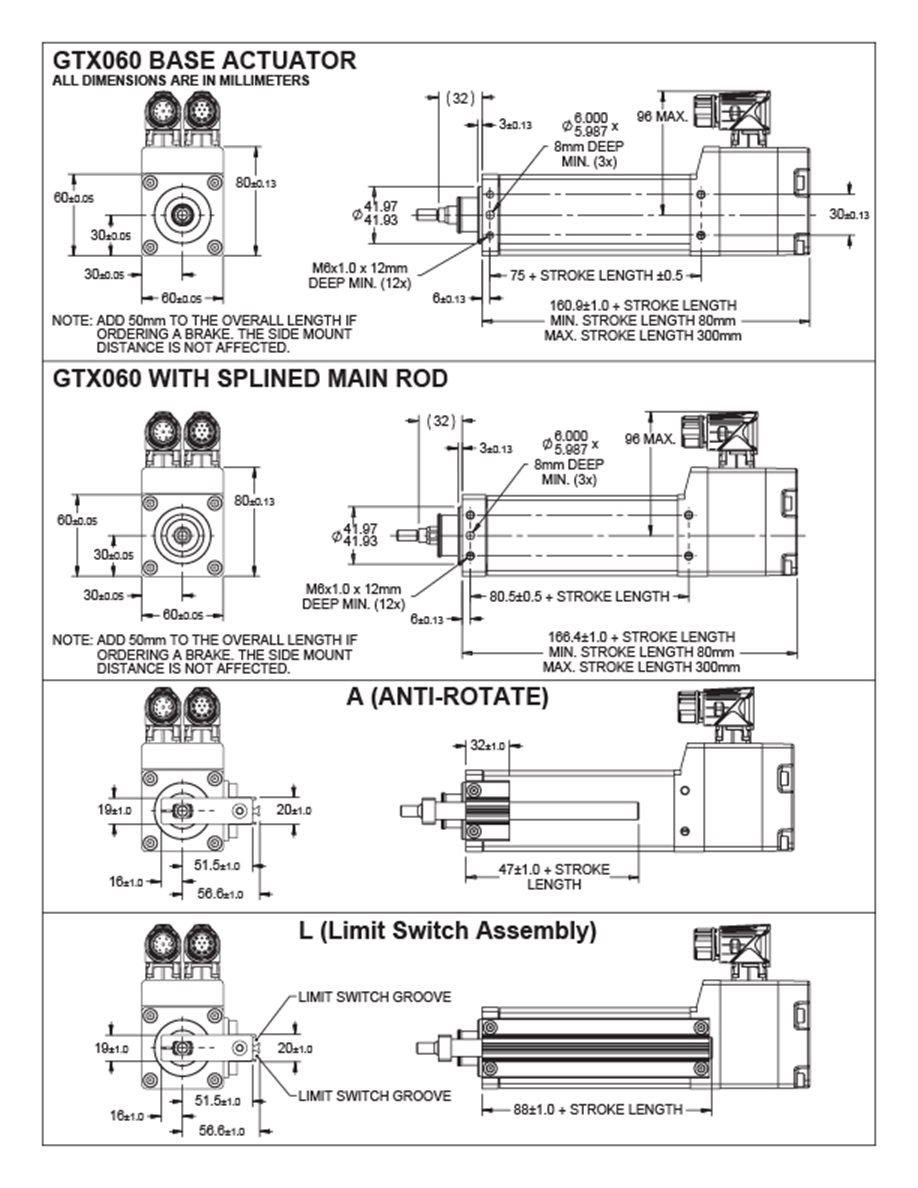

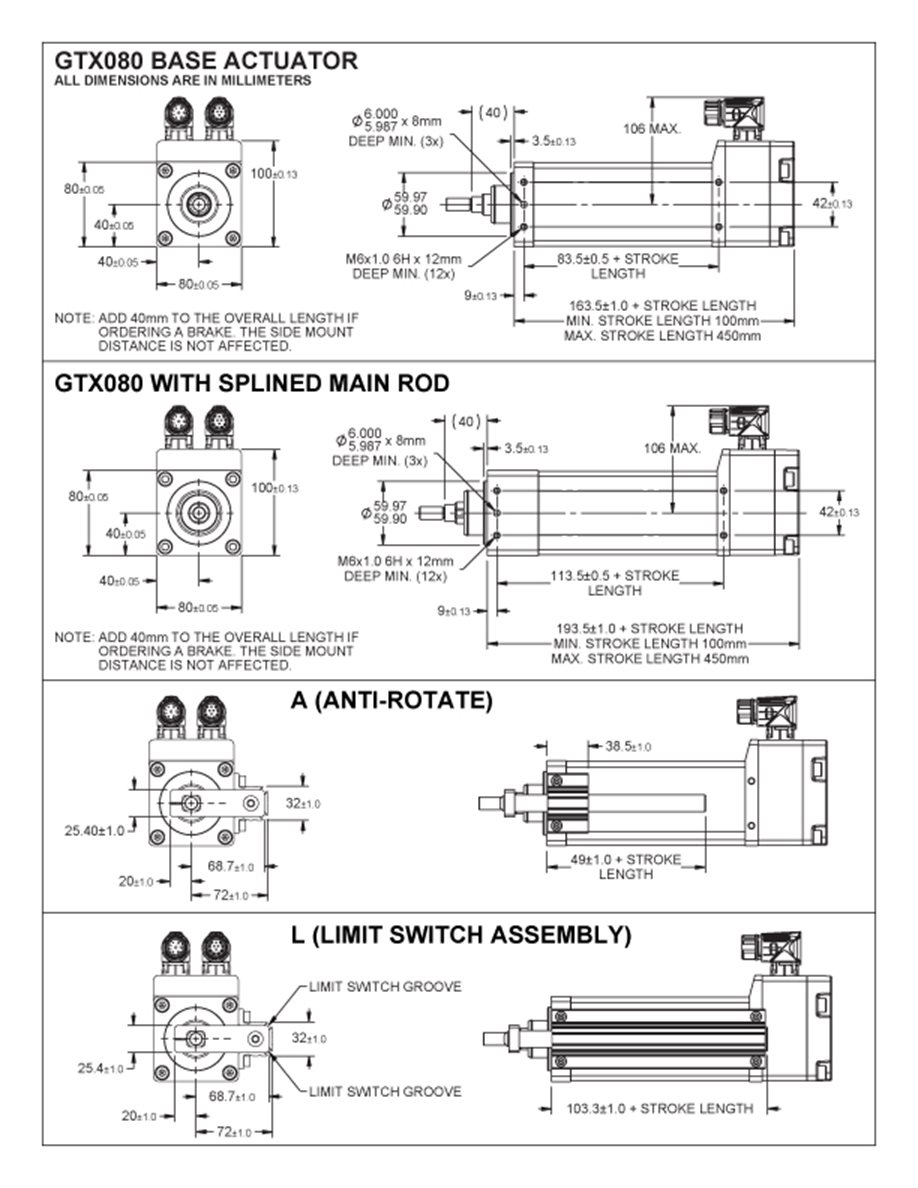

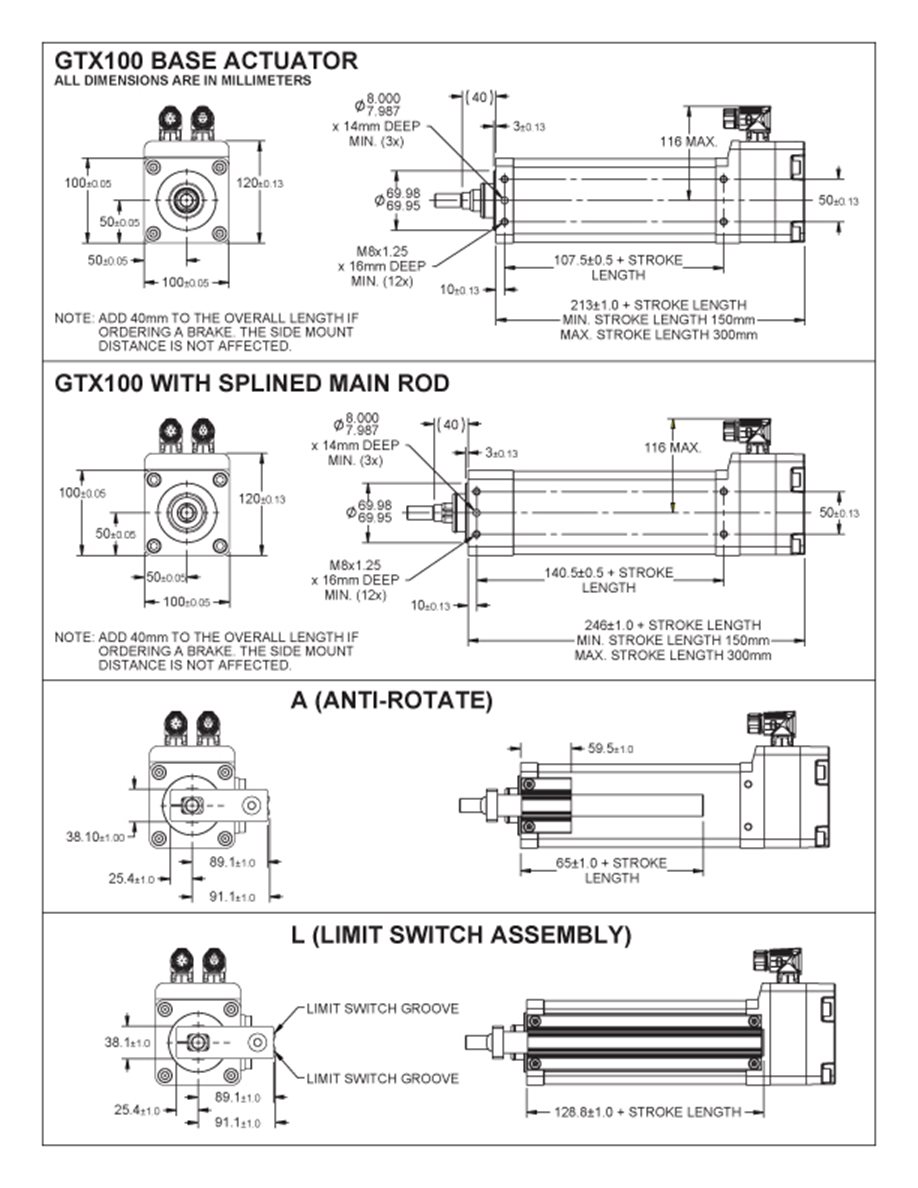

Anti-Rotate, External

This assembly restricts the actuator output rod from rotating when the load is not held by another method. Shorter actuators have a single anti-rotation mechanism; longer lengths have a mechanism on both sides.

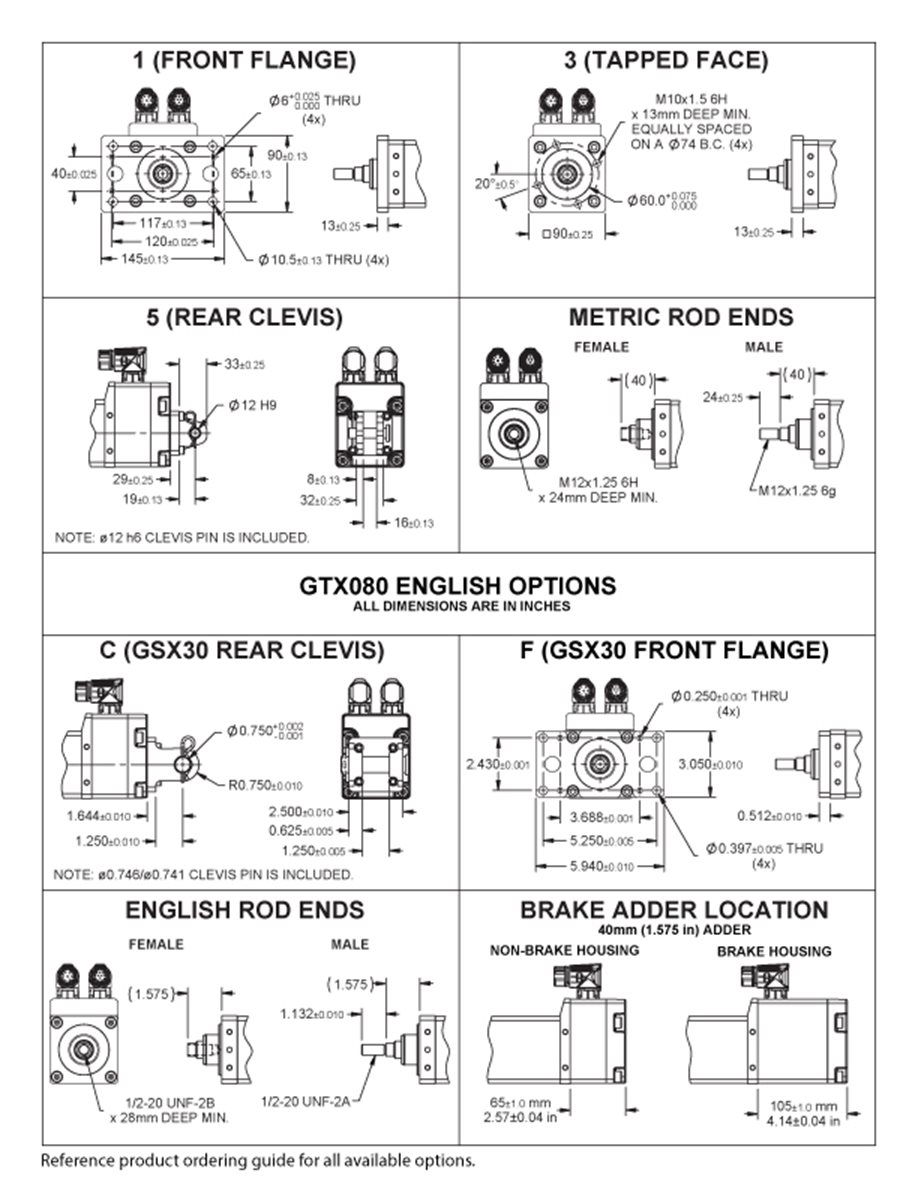

Front Mounting Flange

Front mounting flange, includes thru-holes for face-mounting.

Internal Anti-Rotate (Splined Rod)

A ball spline shafting main rod with a ball spline nut that replaces the standard front seal and bushing assembly. This rod restricts rotation without the need for an external mechanism. The rod diameter will be the closest metric equivalent to our standard rod sizes. Since this option is NOT sealed, it is not suitable for environments in which contaminants may enter the actuator.

Limit Switch Housing/ Anti-Rotate Assembly

External travel switches indicate travel to the controller and are adjustable for either the home or end position. Switches not included.

Rear Clevis, Metric

Rear clevis mount, allows actuator to pivot while in motion

Stainless Steel Rod Option

All thread options on the GTX product line are available in 17-4 stainless steel. This option provides improved corrosion resistance for the main rod of the actuator. This option can be beneficial in applications where the rod could be exposed to harsh chemicals or outdoor environments.

Tapped Face, Metric

Tapped mounting holes in front flange face, allows face-mounting of actuator.