Distribution portal

- Home

-

Industrial - Exlar®

- Exlar Products

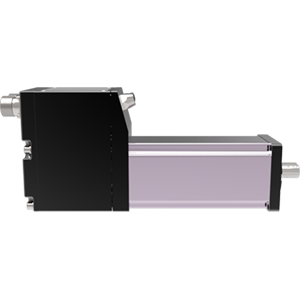

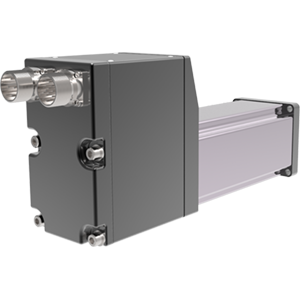

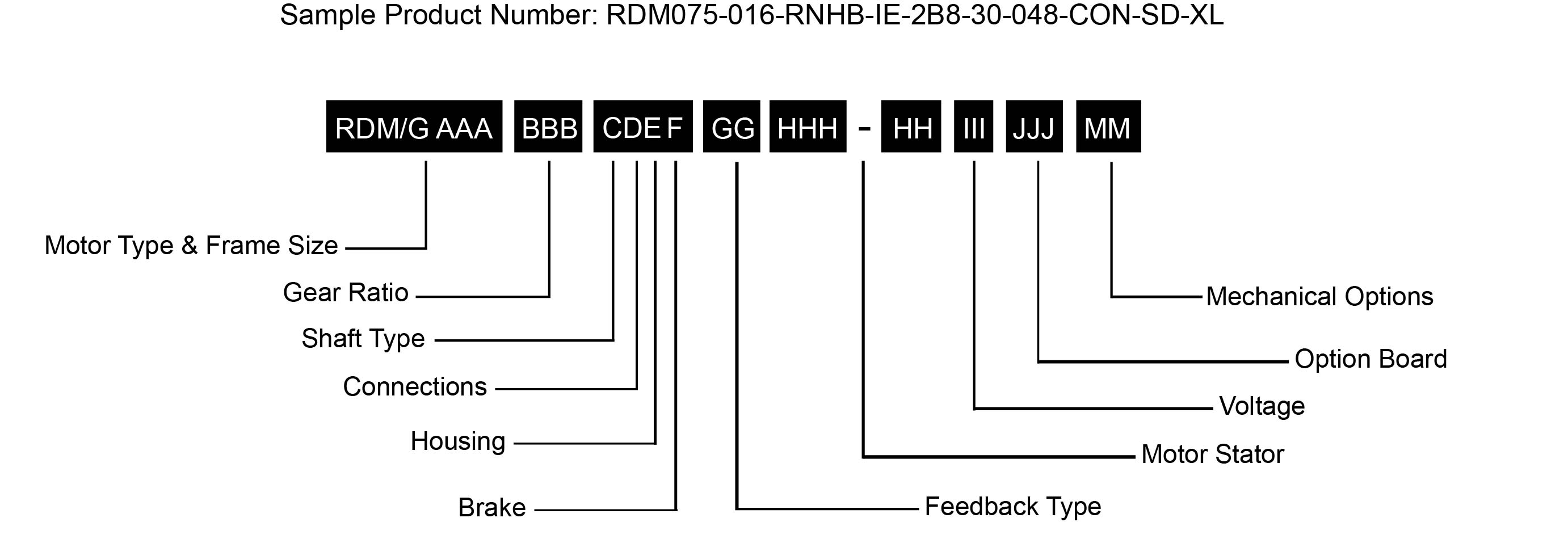

- Universal Linear Actuators

- Integrated Motor | Actuators

- Intelligent Drive | Motor | Actuators

- Rotary Actuators

- Exlar Legacy Product Support

- Industries

- Automotive / Tire

- Food & Beverage / Packaging

- Oil & Gas

- Plastics

- Forestry

- Entertainment / Simulation

- Other Industries

- Resources

- Returned Goods Authorization

- Exlar Product Manuals

- Brochures / Catalogs

- Case Studies

- Exlar Product Videos

- Actuator Technical Tips

- White Papers

- Online Tools

- ASSIGN Motor Selection

- Exact Sizing & Selection Tool

- Software & Downloads

- About Us

- About Exlar Automation

- Rockwell Automation Support

- Careers

- Certifications

- Aerospace

- Ground & Naval Defense

- InfoCenter

- News & Events

- Contact Us

Exlar Products

Universal Linear Actuators

Integrated Motor | Actuators

Intelligent Drive | Motor | Actuators

Rotary Actuators

Exlar Legacy Product Support

Industries

Automotive / Tire

Food & Beverage / Packaging

Oil & Gas

Plastics

Forestry

Entertainment / Simulation

Other Industries