Distribution portal

- Home

-

Industriell - Exlar®

- Exlar Produkte

- Universelle Linearantriebe

- Integrierte Motor-| Aktoren

- Intelligent Drive | Motor-| Aktoren

- Drehantriebe

- Industrien

- Automobil-/EV-Batterie

- Lebensmittel & Getränke / Verpackung

- Öl- und Gasindustrie

- Kunststoffe

- Fortstwirtschaft

- Unterhaltung / Simulation

- Sonstige Branchen

- Betriebsmittel

- Returned Goods Authorization

- Produkthandbücher

- Broschüren / Kataloge

- Fallstudien

- Exlar Videos

- Technische Tipps für Aktuatoren

- Whitepapers

- Online-Tools

- Exact Dimensionierungs- und Auswahlwerkzeug

- Software & Downloads

- Über uns

- Über Exlar

- Allgemeine Geschäftsbedingungen (AGB)

- Zertifizierungen

- Ressourcen

- Nachrichten

- Kontaktieren Sie uns

Exlar Produkte

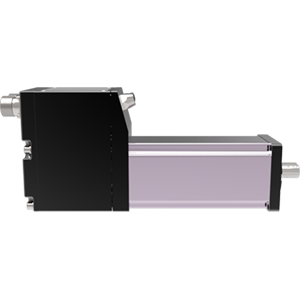

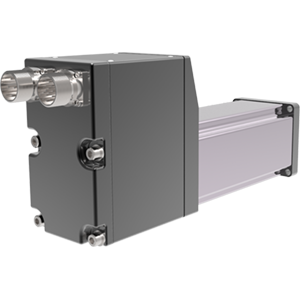

Universelle Linearantriebe

Integrierte Motor-| Aktoren

Intelligent Drive | Motor-| Aktoren

Drehantriebe

Industrien

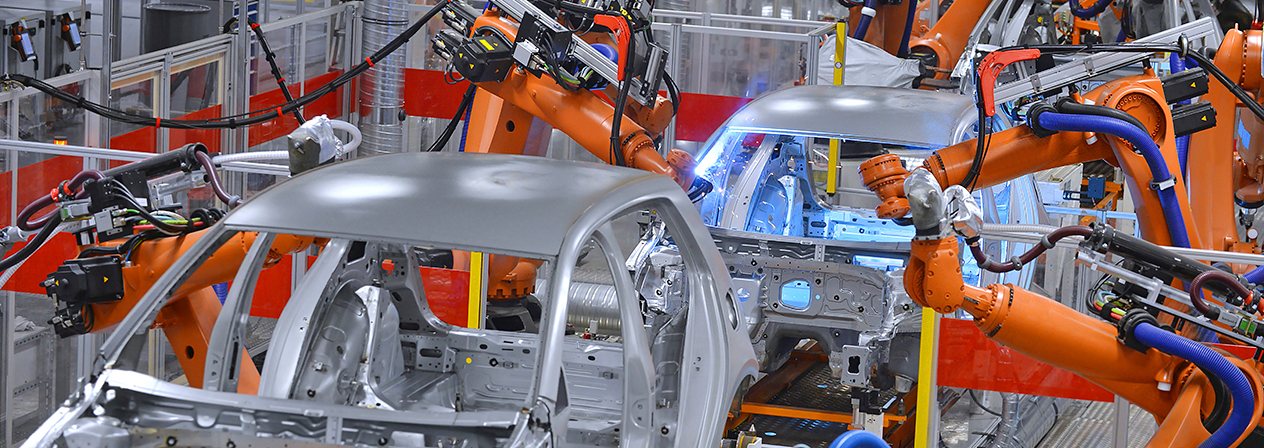

Automobil-/EV-Batterie

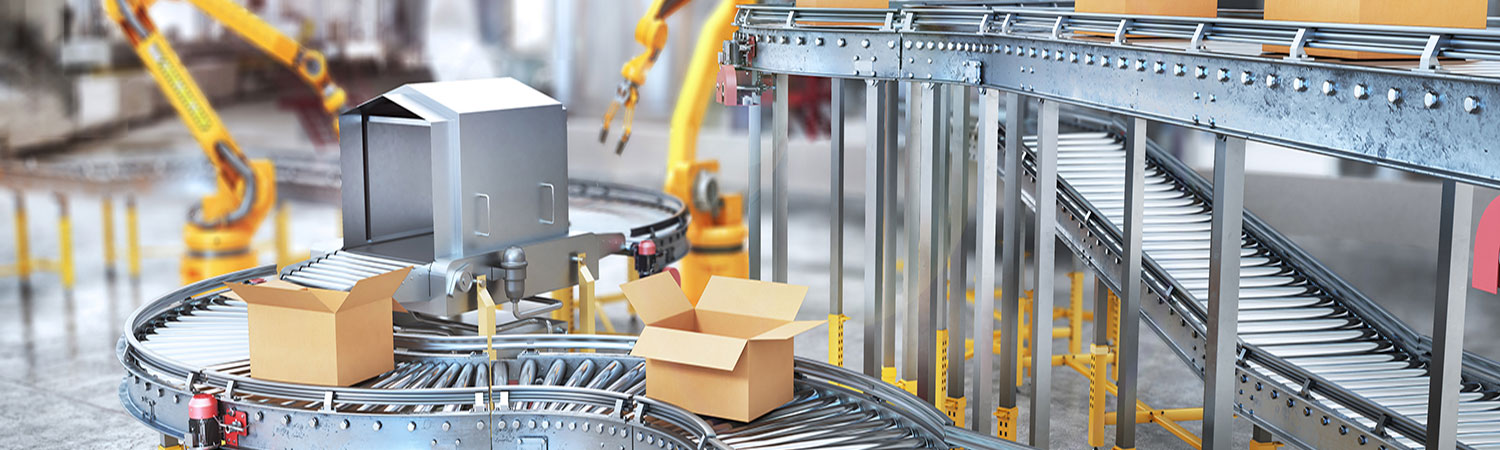

Lebensmittel & Getränke / Verpackung

Öl- und Gasindustrie

Kunststoffe

Fortstwirtschaft

Unterhaltung / Simulation

Sonstige Branchen