Industrial - Exlar

| 型 | 框架尺寸毫米(英寸) | 齿轮比 X:1 | 最大输出扭矩(齿轮) Nm (lbf) | 输出速度(转速) |

| RDM/G060 | 60 (2.36) | 4, 5, 10, 16, 20, 25, 40, 50,100 | 68.1 (603) | 5000/ratio |

| RDM/G075 | 75 (2.95) | 4, 5, 10 | 182.8 (1,618) | 4000/ratio |

| RDM/G090 | 90 (3.54) | 4, 5, 10, 16, 20, 25, 40, 50,100 | 234.8 (2,078) | 3300/ratio |

Tritex II 直流供电旋转执行器在单个紧凑的封装中集成了伺服驱动器、数字定位器和伺服电机。 这些先进的执行器提供市场上最高的功率密度和最小的伺服驱动器件。 其小尺寸和创新设计使其能够轻松地将全电子解决方案整合到现有液压或气动缸的空间中。 现在,您可以使用单个完全集成的设备精确控制运动并解决您的应用要求。

直流供电的Tritex II旋转执行器集成了750 W伺服放大器和功能强大的运动控制器。 这些旋转电机和齿轮电机始终如一地提供高响应和精确控制。 使用您的PC,您可以快速轻松地对执行器进行编程,以遵循模拟信号(电压或电流),代表您喜欢的扭矩,速度或位置。 从 4:1 到 100:1 的齿轮比可提供充足的功率,以满足各种需要高调节比和精度的应用。 标准功能包括位置的模拟跟随、复合移动、移动链接以及每次移动的单独扭矩控制。 Tritex II是大多数运动控制应用的理想解决方案。

这种坚固的旋转执行器解决方案具有出色的可靠性和性能,并具有小尺寸。 伺服驱动器和数字定位器安装在单个密封封装中,空间要求降至最低。 创新的集成设计消除了与安装和布线面板相关的人工成本。 该解决方案只需要一根经济型直流电源线和一根用于数字和模拟 I/O 的标准通信电缆。 此外,也不需要昂贵,高维护的伺服电缆,相关的长距离信号问题已成为过去。

快速数据 | |

|---|---|

| 型号: | RDM旋转电动机 RDG旋转齿轮电动机 |

| 框架尺寸: | 2.3, 2.9, 3.5英寸(60, 75, 90毫米) |

| 齿轮比: | 4:1, 5:1, 10:1, 16:1, 20:1, 25:1, 40:1, 50:1, 100:1 |

| 最大输出转矩: | 高达2078磅力-英寸(235牛米) |

| 输出速度: | 3300,4000,5000转/分每齿轮比 |

| 标准/额定值: | CE; UL 508 C类型4外壳; CSA 139; CSA I类2区A,B,C和D组; IP66S标准; IEC 61800-5-1驱动器安全标准 |

| |

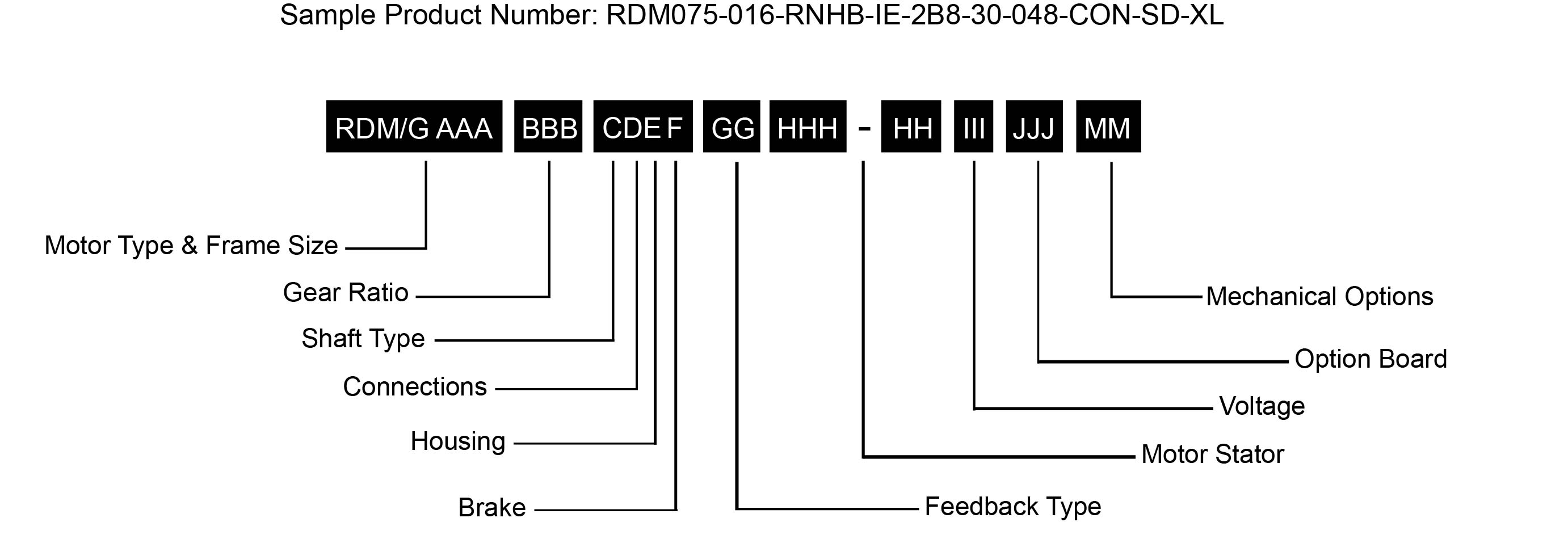

RDM/G = Motor Type | HHH-HH = Motor Stators - All 8 Pole Standard Features |

笔记 :

1. 有关扩展温度操作,请咨询工厂以获取型号。

2. 需要客户提供的以太网电缆通过 I/O 端口,仅符合 1 类 2 分区标准。 在 60 毫米上也不知道。

3. 订购 TDM、RDM 或 RDG 60 mm 或其他尺寸的带顶部安装连接器时,必须将用于自动对焦反馈的备用电池安装在外部。 提供 DIN 导轨安装板(极性 PN 48224)和电池 (PN T2BAT2)。

* 某些选项并非在每个配置中都可用。 对于上面未列出的选项或特价,请联系您当地的 Exlar 代表.

| STATOR | 1 STACK | 2 STACK | 3 STACK | |

|---|---|---|---|---|

| RPM at 48 VDC | 5000 | 5000 | 4000 | |

| Continuous Torque | lbf-in (Nm) | 6.8 (0.76) | 10.5 (1.18) | 13 (1.47) |

| Peak Torque | lbf-in (Nm) | 12.8 (1.44) | 13.3 (1.5) | 17 (1.92) |

| Drive Current @ Continuous Torque | Amps | 14.8 | 21.5 | 21.5 |

| Operating Temperature Range** (-40˚C available, consult Exlar) |

-20 to 65˚ C | |||

| Maximum Continuous Power Supply Current* | Amps | 8 | 11 | 13 |

*Power supply current is based on software current limit, not thermal limit. Consideration for peak current should also be considered when sizing power supplies. For output torque of RDG gearmotors, multiply by ratio and efficiency. Please note maximum allowable output torques found at bottom of page.

**Ratings based on 40˚ C ambient conditions.

| STATOR | 1 STACK | 2 STACK | 3 STACK | |

|---|---|---|---|---|

| RDM Motor Armature Inertia (+/-5%) | lb-in-sec^2 (kg-cm^2) | 0.000237 (0.268) | 0.000413 (0.466) | 0.000589 (0.665) |

| RDG Gearmotor Armature Inertia* | lbf-in-sec^2 (kg-cm^2) | 0.000226 (0.255) | 0.000401 (0.453) | 0.000576 (0.651) |

*Add armature inertia to gearing inertia for total inertia.

| RPM | 50 | 100 | 250 | 500 | 1000 | 3000 |

|---|---|---|---|---|---|---|

| RDM060 lbf (N) | 250 (1112) | 198 (881) | 148 (658) | 116 (516) | 92 (409) | 64 (285) |

| RDG060 lbf (N) | 189 (841) | 150 (667) | 110 (489) | 88 (391) | 70 (311) | 48 (214) |

Side load ratings shown above are for 10,000 hour bearing life at 25 mm from motor face at given rpm.

| MODEL | RATIO | MAXIMUM ALLOWABLE OUTPUT TORQUE-SET BY USER LBF-IN (NM) |

1000 RPM LBF-IN (NM) | 3000 RPM LBF-IN (NM) | 5000 RPM LBF-IN (NM) |

|---|---|---|---|---|---|

| RDG060-004 | 4:1 | 603 (68.1) | 144 (16.2) | 104 (11.7) | 88 (9.9) |

| RDG060-005 | 5:1 | 522 (58.9) | 170 (19.2) | 125 (14.1) | 105 (11.9) |

| RDG060-010 | 10:1 | 327 (36.9) | 200 (22.6) | 140 (15.8) | 120 (13.6) |

| RDG060-016 | 16:1 | 603 (68.1) | 224 (25.3) | 160 (18.1) | 136 (15.4) |

| RDG060-020 | 20:1 | 603 (68.1) | 240 (27.1) | 170 (19.2) | 146 (16.5) |

| RDG060-025 | 25:1 | 522 (58.9) | 275 (31.1) | 200 (22.6) | 180 (20.3) |

| RDG060-040 | 40:1 | 603 (68.1) | 288 (32.5) | 208 (23.5) | 180 (20.3) |

| RDG060-050 | 50:1 | 522 (58.9) | 340 (38.4) | 245 (27.7) | 210 (23.7) |

| RDG060-100 | 100:1 | 327 (36.9) | 320 (36.1) | 280 (31.6) | 240 (27.1) |

Output Torque at Motor Speed for 10,000 Hour Life. Two torque ratings for the RDG gearmotors are given in the table above. The left hand columns give the maximum (peak) allowable output torque for the indicated ratios of each size RDG gearmotor. This is not the rated output torque of the motor multiplied by the ratio of the reducer. It is possible to select a configuration of the motor selection and gear ratio such that the rated motor torque, multiplied by the gear ratio exceeds these ratings. It is the responsibility of the user to ensure that the settings of the system do not allow these values to be exceeded. The right hand columns give the output torque at the indicated speed which will result in 10,000 hour life (L10). The setup of the system will determine the actual output torque and speed.

| GEAR STAGES | LBF-IN-SEC^2 | (KG-CM^2) |

|---|---|---|

| Single Reduction | ||

| 4:1 | 0.0000132 | (0.149) |

| 5:1 | 0.0000087 | (0.00984) |

| 10:1 | 0.0000023 | (0.00261) |

| Double Reduction | ||

| 16:1 | 0.0000121 | (0.0137) |

| 20:1, 25:1 | 0.0000080 | (0.00906) |

| 40:1, 50:1, 100:1 | 0.0000021 | (0.00242) |

| SINGLE REDUCTION | DOUBLE REDUCTION | |

|---|---|---|

| Backlash at 1% Rated Torque | 10 Arc min | 13 Arc min |

| Efficiency | 91% | 86% |

| RDM060 WITHOUT GEARS | RDG060 WITH 1 STAGE GEARING | RDG060 WITH 2 STAGE GEARING | ADDED WEIGHT FOR BRAKE | |

|---|---|---|---|---|

| 1 Stack Stator lb (kg) | 3.0 (1.4) | 7.5 (3.4) | 9.3 (4.2) | 0.6 (0.3) |

| 2 Stack Stator lb (kg) | 4.1 (1.9) | 8.6 (3.9) | 10.4 (4.7) | 0.6 (0.3) |

| 3 Stack Stator lb (kg) | 5.2 (2.4) | 9.7 (4.4) | 11.5 (5.2) | 0.6 (0.3) |

| STATOR | 1 STACK | 2 STACK | 3 STACK | |

|---|---|---|---|---|

| RPM at 48 VDC | 4000 | 3000 | 2000 | |

| Continuous Torque | lbf-in (Nm) | 13 (1.46) | 18.5 (2.09) | 29 (3.28) |

| Peak Torque | lbf-in (Nm) | 18.9 (2.08) | 28 (3.16) | 41 (4.63) |

| Drive Current @ Continuous Torque | Amps | 22 | 22 | 22 |

| Operating Temperature Range** (-40˚C available, consult Exlar) |

-20 to 65˚ C | |||

| Maximum Continuous Power Supply Current* | Amps | 15 | 18 | 18 |

*Power supply current is based on software current limit, not thermal limit. Consideration for peak current should also be considered when sizing power supplies. For output torque of RDG gearmotors, multiply by ratio and efficiency. Please note maximum allowable output torques shown below.

**Ratings based on 40˚ C ambient conditions.

| STATOR | 1 STACK | 2 STACK | 3 STACK | |

|---|---|---|---|---|

| RDM Motor Armature Inertia (+/-5%) | lb-in-sec^2 (kg-cm^2) | 0.000545 (0.6158) | 0.000973 (1.0996) | 0.001401 (1.5834) |

| RDG Gearmotor Armature Inertia* (+/-5%) | lbf-in-sec^2 (kg-cm^2) | 0.000660 (0.7450) | 0.001068 (1.2057) | 0.001494 (1.6868) |

*Add armature inertia to gearing inertia for total inertia.

| RPM | 50 | 100 | 250 | 500 | 1000 | 3000 |

|---|---|---|---|---|---|---|

| RDM075 lbf (N) | 278 (1237) | 220 (979) | 162 (721) | 129 (574) | 102 (454) | 71 (316) |

| RDG075 lbf (N) | 343 (1526) | 272 (1210) | 200 (890) | 159 (707) | 126 (560) | 88 (391) |

*Side load ratings shown above are for 10,000 hour bearing life at 25 mm from motor face at given rpm.

| MODEL | RATIO | MAXIMUM ALLOWABLE OUTPUT TORQUE-SET BY USER LBF-IN (NM) |

1000 RPM LBF-IN (NM) | 2500 RPM LBF-IN (NM) | 4000 RPM LBF-IN (NM) |

|---|---|---|---|---|---|

| RDG075-004 | 4:1 | 1618 (182.8) | 384 (43.4) | 292 (32.9) | 254 (28.7) |

| RDG075-005 | 5:1 | 1446 (163.4) | 395 (44.6) | 300 (33.9) | 260 (29.4) |

| RDG075-010 | 10:1 | 700 (79.1) | 449 (50.7) | 341 (38.5) | 296 (33.4) |

Output Torque at Motor Speed for 10,000 Hour Life. Two torque ratings for the RDG gearmotors are given in the table above. The left hand columns give the maximum (peak) allowable output torque for the indicated ratios of each size RDG gearmotor. This is not the rated output torque of the motor multiplied by the ratio of the reducer. It is possible to select a configuration of the motor selection and gear ratio such that the rated motor torque, multiplied by the gear ratio exceeds these ratings. It is the responsibility of the user to ensure that the settings of the system do not allow these values to be exceeded. The right hand columns give the output torque at the indicated speed which will result in 10,000 hour life (L10). The setup of the system will determine the actual output torque and speed.

| SINGLE REDUCTION (+/-5%) | ||

|---|---|---|

| Gear Stages | lbf-in-sec^2 | (kg-cm^2) |

| 4:1 | 0.000095 | (0.107) |

| 5:1 | 0.000062 | (0.069) |

| 10:1 | 0.000117 | (0.019) |

| SINGLE REDUCTION | |

|---|---|

| Backlash at 1% Rated Torque | 10 Arc min |

| Efficiency | 91% |

| RDM075 WITHOUT GEARS | RDG075 WITH 1 STAGE GEARING | ADDED WEIGHT FOR BRAKE | |

|---|---|---|---|

| 1 Stack Stator lb (kg) | 7.4 (3.4) | 9.8 (4.4) | 1.0 (0.5) |

| 2 Stack Stator lb (kg) | 9.2 (4.2) | 11.6 (5.3) | 1.0 (0.5) |

| 3 Stack Stator lb (kg) | 11 (4.9) | 13.4 (6.1) | 1.0 (0.5) |

| STATOR | 1 STACK | 2 STACK | 3 STACK | |

|---|---|---|---|---|

| RPM at 48 VDC | 3300 | 1800 | 1400 | |

| Continuous Torque | lbf-in (Nm) | 17 (1.92) | 28 (3.16) | 41 (4.63) |

| Peak Torque | lbf-in (Nm) | 21.8 (2.46) | 36 (4.07) | 52.8 (5.97) |

| Drive Current @ Continuous Torque | Amps | 22 | 22 | 22 |

| Operating Temperature Range** (-40˚C available, consult Exlar) |

-20 to 65˚ C | |||

| Maximum Continuous Power Supply Current* | Amps | 18 | 18 | 18 |

*Power supply current is based on software current limit, not thermal limit. Consideration for peak current should also be considered when sizing power supplies. For output torque of RDG gearmotors, multiply by ratio and efficiency. Please note maximum allowable output torques shown below.

**Ratings based on 40˚ C ambient conditions.

| STATOR | 1 STACK | 2 STACK | 3 STACK | |

|---|---|---|---|---|

| RDM Motor Armature Inertia (+/-5%) | lb-in-sec^2 (kg-cm^2) | 0.00054 (0.609) | 0.00097 (1.09) | 0.00140 (1.58) |

| RDG Gearmotor Armature Inertia* (+/-5%) | lbf-in-sec^2 (kg-cm^2) | 0.00114 (1.29) | 0.00157 (1.77) | 0.00200 (2.26) |

*Add armature inertia to gearing inertia for total inertia.

| RPM | 50 | 100 | 250 | 500 | 1000 | 3000 |

|---|---|---|---|---|---|---|

| RDM090 lbf (N) | 427 (1899) | 340 (1512) | 250 (1112) | 198 (881) | 158 (703) | 109 (485) |

| RDG090 lbf (N) | 350 (1557) | 278 (1237) | 205 (912) | 163 (725) | 129 (574) | 89 (396) |

Side load ratings shown above are for 10,000 hour bearing life at 25 mm from motor face at given rpm.

| MODEL | RATIO | MAXIMUM ALLOWABLE OUTPUT TORQUE-SET BY USER LBF-IN (NM) |

1000 RPM LBF-IN (NM) | 2500 RPM LBF-IN (NM) | 3300 RPM LBF-IN (NM) |

|---|---|---|---|---|---|

| RDG090-004 | 4:1 | 2078 (234.8) | 698 (78.9) | 530 (59.9) | 488 (55.1) |

| RDG090-005 | 5:1 | 1798 (203.1) | 896 (101.2) | 680 (76.8) | 626 (70.7) |

| RDG090-010 | 10:1 | 1126 (127.2) | 1043 (117.8) | 792 (89.5) | 729 (82.4) |

| RDG090-016 | 16:1 | 2078 (234.8) | 1057 (119.4) | 803 (90.7) | 739 (83.5) |

| RDG090-020 | 20:1 | 2078 (234.8) | 1131 (127.8) | 859 (97.1) | 790 (89.3) |

| RDG090-025 | 25:1 | 1798 (203.1) | 1452 (164.1) | 1103 (124.6) | 1015 (114.7) |

| RDG090-040 | 40:1 | 2078 (234.8) | 1392 (157.3) | 1057 (119.4) | 973 (109.9) |

| RDG090-050 | 50:1 | 1798 (203.1) | 1787 (201.9) | 1358 (153.4) | 1249 (141.1) |

| RDG090-100 | 100:1 | 1126 (127.2) | 1100 (124.3) | 1100 (124.3) | 1100 (124.3) |

Output Torque at Motor Speed for 10,000 Hour Life.Two torque ratings for the RDG gearmotors are given in the table above. The left hand columns give the maximum (peak) allowable output torque for the indicated ratios of each size RDG gearmotor. This is not the rated output torque of the motor multiplied by the ratio of the reducer. It is possible to select a configuration of the motor selection and gear ratio such that the rated motor torque, multiplied by the gear ratio exceeds these ratings. It is the responsibility of the user to ensure that the settings of the system do not allow these values to be exceeded. The right hand columns give the output torque at the indicated speed which will result in 10,000 hour life (L10). The setup of the system will determine the actual output torque and speed.

| GEAR STAGES | LBF-IN-SEC^2 | (KG-CM^2) |

|---|---|---|

| Single Reduction | ||

| 4:1 | 0.0000154 | (0.174) |

| 5:1 | 0.0000100 | (0.113) |

| 10:1 | 0.0000265 | (0.0300) |

| Double Reduction | ||

| 16:1 | 0.000115 | (0.130) |

| 20:1, 25:1 | 0.0000756 | (0.0854) |

| 40:1, 50:1, 100:1 | 0.0000203 | (0.0230) |

| SINGLE REDUCTION | DOUBLE REDUCTION | |

|---|---|---|

| Backlash at 1% Rated Torque | 10 Arc min | 13 Arc min |

| Efficiency | 91% | 86% |

| RDM090 WITHOUT GEARS | RDG090 WITH 1 STAGE GEARING | RDG090 WITH 2 STAGE GEARING | ADDED WEIGHT FOR BRAKE | |

|---|---|---|---|---|

| 1 Stack Stator lb (kg) | 12.5 (5.7) | 20.5 (9.3) | 23.5 (10.7) | 1.5 (0.7) |

| 2 Stack Stator lb (kg) | 15.5 (7.0) | 23.5 (10.7) | 26.5 (12) | 1.5 (0.7) |

| 3 Stack Stator lb (kg) | 18.5 (8.4) | 26.5 (12.0) | 29.5 (13.4) | 1.5 (0.7) |

Tritex II系列执行器是智能执行器,具有板载控制和通信功能,支持分布式控制和IIoT架构。 这导致:

Please log in or register to use our quote request tool, with this you can view and download 3D and 2D models and drawings, as well as build and submit a quote request.

If you do not have a login, please proceed to the registration page

RegisterIf you currently have an Exlar website account and would like to delete it, please contact